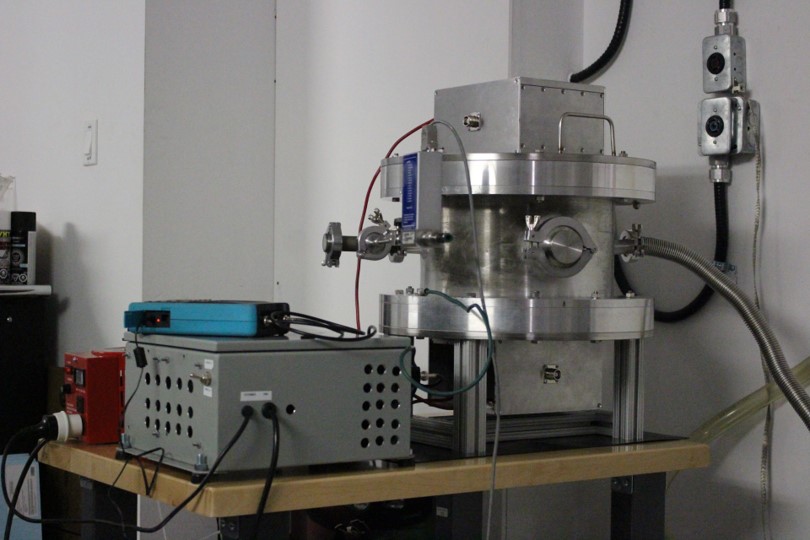

Just a quick update for those who might be curious, like many companies Meaglow Ltd answered government calls for action during the Covid-19 Pandemic. We had a gas plasma unit (shown in the image below) we were using for another project and thought we could re-purpose it to re-sterilize N-95 and surgical masks – which were in short supply at the time. So what happened with that effort?

Well, we didn’t have the capital to pursue the plasma sterilizer ourselves, but four months after having the idea we did manage to get some modest government funding from the Canadian National Research Council, through their IRAP program. It was enough to do some testing and a bit of development, but in retrospect, not really the amount you would need to rush a product to market for an emergency. Regardless, we did make progress. The plasma sterilizer would have had to have been licensed as a class two medical device by Health Canada if it were to go into use. However, that licensing didn’t just involve being able to demonstrate the deactivation of Covid-19 – for Health Canada and the American FDA more stringent requirements were in place than for solutions used in other parts of the world. In particular the sterilizer had to deactivate bacterial spore, which are much harder to destroy than SARS like viruses, such as Covid-19. Also, we had to find conditions where the masks would not be adversely affected by the plasma.

Well, we didn’t have the capital to pursue the plasma sterilizer ourselves, but four months after having the idea we did manage to get some modest government funding from the Canadian National Research Council, through their IRAP program. It was enough to do some testing and a bit of development, but in retrospect, not really the amount you would need to rush a product to market for an emergency. Regardless, we did make progress. The plasma sterilizer would have had to have been licensed as a class two medical device by Health Canada if it were to go into use. However, that licensing didn’t just involve being able to demonstrate the deactivation of Covid-19 – for Health Canada and the American FDA more stringent requirements were in place than for solutions used in other parts of the world. In particular the sterilizer had to deactivate bacterial spore, which are much harder to destroy than SARS like viruses, such as Covid-19. Also, we had to find conditions where the masks would not be adversely affected by the plasma.

In the end we were able to do both. The local Thunder Bay company BioNorth Solutions helped us with the bacterial spore measurements. We made a special gas plasma system, purpose built for the job (shown in the main image for this article) and found conditions that could deactivate bacterial spore while leaving the masks untarnished.This was no mean feat as in the past only hydrogen peroxide plasmas had been successful in deactivating bacterial spore, but we were able to achieve this result without that noxious vapour. Unfortunately, it turned out that the requirement for equipment for Covid-19 was a bubble. Even now with the on-going pandemic there is no further demand for equipment to re-sterilize masks. The emergency provisions that allowed mask re-sterilization of single use masks have been largely removed. Many of the companies who answered the call to action are now sitting on stock that they may never be able to sell. Well, at least not until the next pandemic hits. Interestingly, there doesn’t appear to be any government plans to stockpile such equipment to address future shortages or pandemics. We were probably lucky in that we didn’t do too much development after the IRAP funding ended, as we soon realised it wasn’t going to lead anywhere. Our company losses were minimal. Probably not so for many of the other companies who answered the call, I expect most of those won’t be too anxious to help next time around.

So what now? Well, we have a nice bit of equipment that did a good job, but it will be mothballed until we can find a use for it. The project did help us develop our plasma technology, so that knowledge may be of use for future development. In the meantime we’re going to look at perhaps publishing the results we had so that if there is ever a need again the information on plasma sterilization will be available for future generations to use.